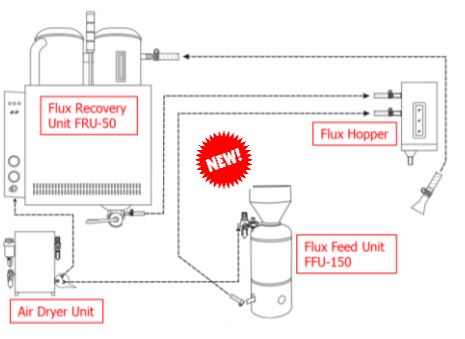

The Flux Recovery System recycles flux in SAW (Submerged Arc Welding) operations. It reduces operational costs for recovering and reusing flux before dust contamination. It also prevents the flux from getting wet because of its heating device, avoiding welding porosity.

Model: FRU-150

- Flux Capacity: 150 kg

- Require Air Pressure: 80-90 PSI

- Air Flow: 20 CFM

- Flux Heater: 0-150 C°

- Vacuum Motor: 3.45 kW (12.5 amps)

- Heater Element: 6 amps

- Flux Recovery: 8-15 kg/min

- Flux Feeding: 2-20 kg/min

- Flux Delivery: Up to 9 m

- Including: Flux Hooper, Flux Low Level Alarm, Bottom Flux Valve, Pulse Dust Removal.

- 25 m Wired Hand Controller. Functions: Vacuum On/Off, Flux Feed On/Off, Hopper Open/Close.

- Packing: 1260 mm x 660 mm x 1650 mm (L x W x H), Weight: 256 kg

- Input Power: 240V/60Hz/3P

Flux Feed Unit FFU-150

Requirements

Require Air Pressure: 80-90 PSI

Air Flow: 20 CFM

Flux Heater: 0-150 C°

Flux Level Alarm: Included

Unit Weight: 300 kg

Input Power: 240V/60Hz/3P

Air Dryer Unit

Requirements

Air Pressure: 80-90 PSI

Air Flow: 20 CFM

Weight: 180 kg

Input Power: 240V/60HZ/3P

Delivery Time:

Within Canada: Three to five business days

USA & US-Mexican border: One week

Latino America: Four weeks

World-Wide: Five to six weeks