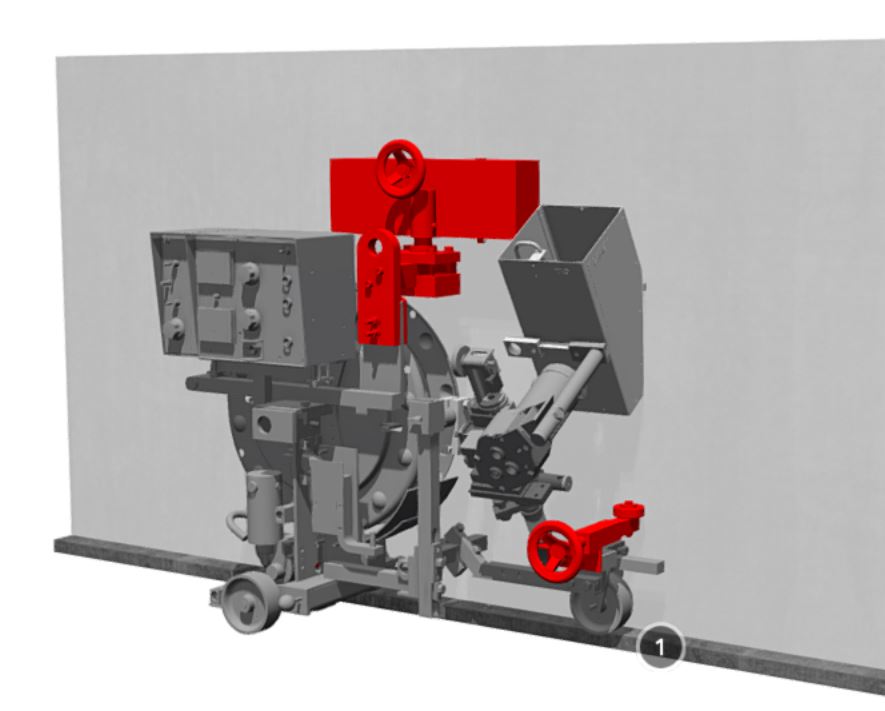

SAW Welding Tractoris a self-propelled Tractor with an Electric Flux Recovery System and a Magnetic Device. The Tractor applies Submerged Arc Welding, more commonly abbreviated to SAW or Sub Arc Welding. SAW is primarily used on carbon steels, stainless steels, and certain nickel alloys. It enhances productivity and consistently produces high-quality welds. SAW Welding Tractor, also known as Submerged Arc Welding Tractor, and Lincoln LT-7 Tractor.

Applications:

Submerged Arc Welding (SAW) on API 650 & API 620 Tanks

1. Welding Floors: Utilize the SAW process for either butt or fillet welds.

2. Welding the Annular Plate to the Tank Shell Bottom: Apply the circumferential SAW process for fillet welds.

Submerged Arc Welding (SAW) Steel Beams & Overhead Cranes

1. Beam Cranes: This includes jib cranes and monorail cranes.

2. Bridge Cranes: Such overhead travelling cranes, overhead bridge cranes, or EOT cranes.

3. H Beams: Also known as Wide Flanges or Universal Columns.

4. I Beams: Referred to as Universal Beams or Rolled Steel Joists.

Package Includes:

1. SAW Tractor

- Input Power:110V, 50/60 Hz, 1P

- Power Source: Lincoln PowerPlus 1000HD

- Lincoln Welding Control

- Welding Head

- Tractor variable speed: From 0.20 to 2.20 m/minute

- Controls: ON/OFF, FWD/REV, & speed potentiometer

- Cross slide: 100 mm (up/down) x 100 mm (left/right)

- Vertical head lifting adjustment: 70 mm

- Head rotation: ±90°

- Head inclination: ±45°

- Wire Reel: For coils 50 or 60 lbs; 12" (ID) x 5" (W)

- Guide Rail: 1 m/each x 3 units

- Control Cable with 14 Pins, male/female with quick connectors: 30 m

- Contact Tips (one of each): 2.40 mm (3/32″), 3.20 mm (1/8″) and 4.0 mm (5/32″)

- Required & Not-included: Welding cable 120 mm², 30 m

2. Electrical Flux Recovery System

- Input Power: 110V, 50/60 Hz, 1P

- Included: Recovery hose x 1 pc (1 m), Flux pick-up nozzle x 1 pc,

Nozzle bracket x 1 pc and Filter bag x 1 pc - Flux Hopper: 4 Litres

- Dimensions (mm): 260 (L) x 220 (W) x 550 (H)

- Net Weight: 6.2 kg

3. Irizar Magnetic Device

Uphold vertical SAW Welding Tractor while one wheel is floating, and it runs fastened by magnets to: a) The Tank Shell, either inside or outside the tank. b) The Crane Beam, H & Beam Webb.

Our company recommends consulting a Certified Welding Engineer (CWEng) to design the welding procedure in accordance with the relevant national and provincial codes and standards. In Canada, CWEngs are certified by the Canadian Welding Bureau (CWB). In contrast, in the USA, they are accredited by the American Society of Mechanical Engineers (ASME), the American Welding Society (AWS), and the American Petroleum Institute (API), among other prestigious organizations worldwide. A CWEng is responsible for designing and selecting appropriate welding parameters, including plate beveling, wire and flux specifications, amperage, voltage, and welding speed, among other factors.

Irizar does not offer training, as the machine is straightforward to operate. However, it must be operated by an experienced Submerged Arc Welding (SAW) Operator. Certification is required for this trade, meaning the operator holds journeyperson certification. Irizar rental facility is available in Wetaskiwin, AB, Canada, where customer welder operators can familiarize themselves with the equipment and obtain coupons for qualifying Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), and Welder Qualification Tests (WQT). Otherwise, we recommend purchasing the machine in advance and making it work in your shop before setting it up on the jobsite

Delivery Time:

Within Canada: Three to five business days

USA & US-Mexican border: One week

Latino America & Worldwide: Two weeks