SUBMERGED ARC WELDING (SAW) TRACTOR

FREQUENTLY ASKED QUESTIONS [FAQ]

1. Does Irizar provide the WPS & PQR? No!. Irizar Heavy Industries recommends consulting a Certified Welding Engineer (CWEng) to design the welding procedure in accordance with the relevant national and provincial codes and standards. In Canada, CWEngs are certified by the Canadian Welding Bureau (CWB). In contrast, in the USA, they are accredited by the American Society of Mechanical Engineers (ASME), the American Welding Society (AWS), and the American Petroleum Institute (API), among other prestigious organizations worldwide. A CWEng is responsible for designing and selecting the appropriate welding parameters, which include plate beveling, wire and flux specifications, amperage, voltage, and welding speed, among other factors.

2. Does Irizar provide the training? No!. Irizar does not offer training, as the machine is straightforward to operate. However, it must be operated by an experienced Submerged Arc Welding (SAW) Operator. Certification is required for this trade, meaning the operator holds a certification as a journeyman. Irizar rental facility is available in Wetaskiwin, AB, Canada, where customer welder operators can familiarize themselves with the equipment and obtain coupons for qualifying Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), and Welder Qualification Tests (WQT). Otherwise, we recommend purchasing the machine in advance and making it work in your shop before setting it up on the jobsite.

KNOWLEDGE BASE [KB]

1. A Submerged Arc Welding (SAW) Tractor, also known as a welding tractor or welding carriage, is a specialized piece of equipment used in welding to automate and enhance the efficiency of the welding process. It is particularly designed for submerged arc welding, which is a welding process where the arc is submerged beneath a layer of flux.

2. Welding Tractor is equipped with a motorized drive system that allows it to move along the workpiece at variable speeds. This automation reduces the need for manual intervention and ensures consistent travel speed.

3. SAW welding involves feeding a continuous wire electrode into the weld zone, and a layer of granular flux shields the arc.

4. Welding tractors come with adjustable parameters such as travel speed, voltage, and wire feed speed.

5. Stability and Consistency: The welding tractor enhances the welding process and high-quality welds.

6. Welding tractors are typically designed to be compatible with various welding power sources. They can be integrated into welding systems to work seamlessly with the power source, wire feeder, and other components.

7. Application: SAW Welding Tractors find applications in various industries such as shipbuilding, pipeline construction, heavy fabrication, and other situations where long and continuous welds are required.

8. Productivity: The automation increased productivity by reducing the time and labour required for welding. Operators can focus on setting parameters and ensuring the quality of the weld.

9. In summary, the SAW Welding Tractors are valuable tools in industrial welding applications, especially for processes that involve long, continuous welds. Their automation features contribute to improved efficiency, consistency, and overall productivity in various welding operations.

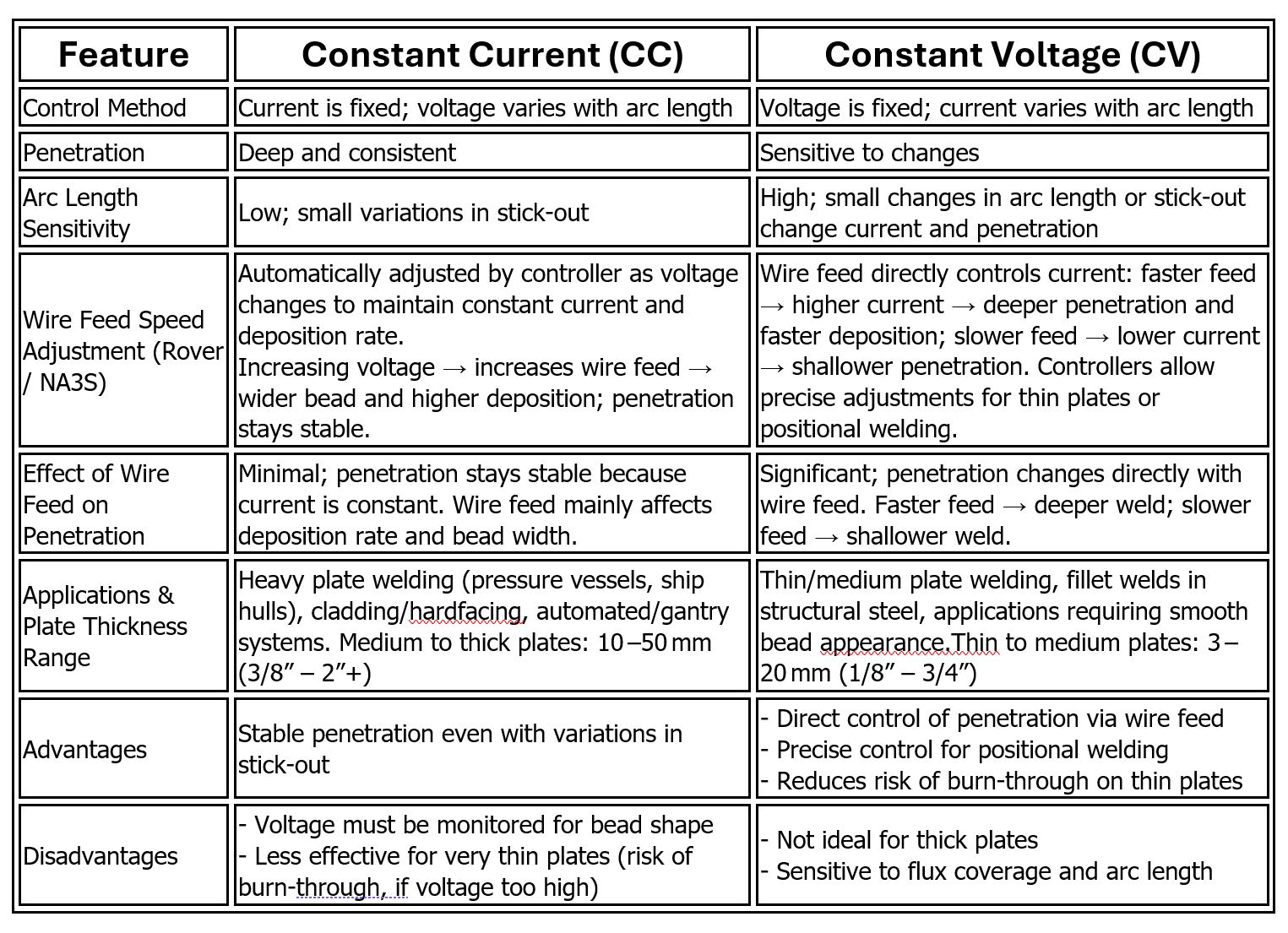

10. SAW systems operate in either Constant Current (CC) or Constant Voltage (CV) modes: Each offers different control characteristics, penetration behaviour, and suitability for various plate thicknesses. Lincoln Power Sources DC 1000, Flex Tech 650 X, or Power Plus 1000 HD, along with Lincoln Controller NA-3S (analog), NA-4 (digital), or the Lincoln Rover Controller, can operate in both CC (Constant Current) and CV (Constant Voltage) Modes. Switching from one mode to another requires changes on the Power Source front panel as well as on the Controller’s Internal Board (Toggle Switch). Lincoln Wire Feeder Head NA-3SF or Irizar Wire Feeder drive at a constant positioning speed to help position the electrode prior to welding. The actual programmed welding wire feed speed adjustment does not occur until an arc has been successfully established — this transition is triggered by sensing weld current or arc voltage, depending on whether the system is configured in [CC or CV mode]. Once the arc is detected, the controller logic switches from constant speed to the set welding wire variable feed speed.

11. Comparison Table: CC vs CV