Irizar Heavy Industries Inc. is a Canadian company based in Edmonton. We take pride in manufacturing the world's largest Tank Lifting Jacks and owning the world's largest stock.

Jack's Model 12-3000 is used to construct API 650 and API 620 Welded Steel Tanks and Bolted Tanks. The construction process is top-to-bottom [instead of the traditional bottom-to-top]. Our system eliminates the need for large cranes. Scaffolding is minimized. The roof is built over the first ring. Tank shell plates are fed at floor level, increasing productivity because personnel at the job site work inside the tank under the roof cover. The process is performed at a maximum height of 6.50 m, encompassing assembly, tack welding, circumferential and longitudinal welding, inspection, and repairs.

Certifications, Test & Safety

Frequently Asked Questions (FAQ]

Knowledge Base [KB]

Tank Lifting Jacks Re-Certification

Irizar Heavy Industries Inc. has developed unique and sophisticated software that calculates the number of jacks required and their respective capacities to ensure safe lifting. The software accounts for the tank's lifting weight and other factors, including tank diameter and height, roof weight, snow, wind, and seismic loads.

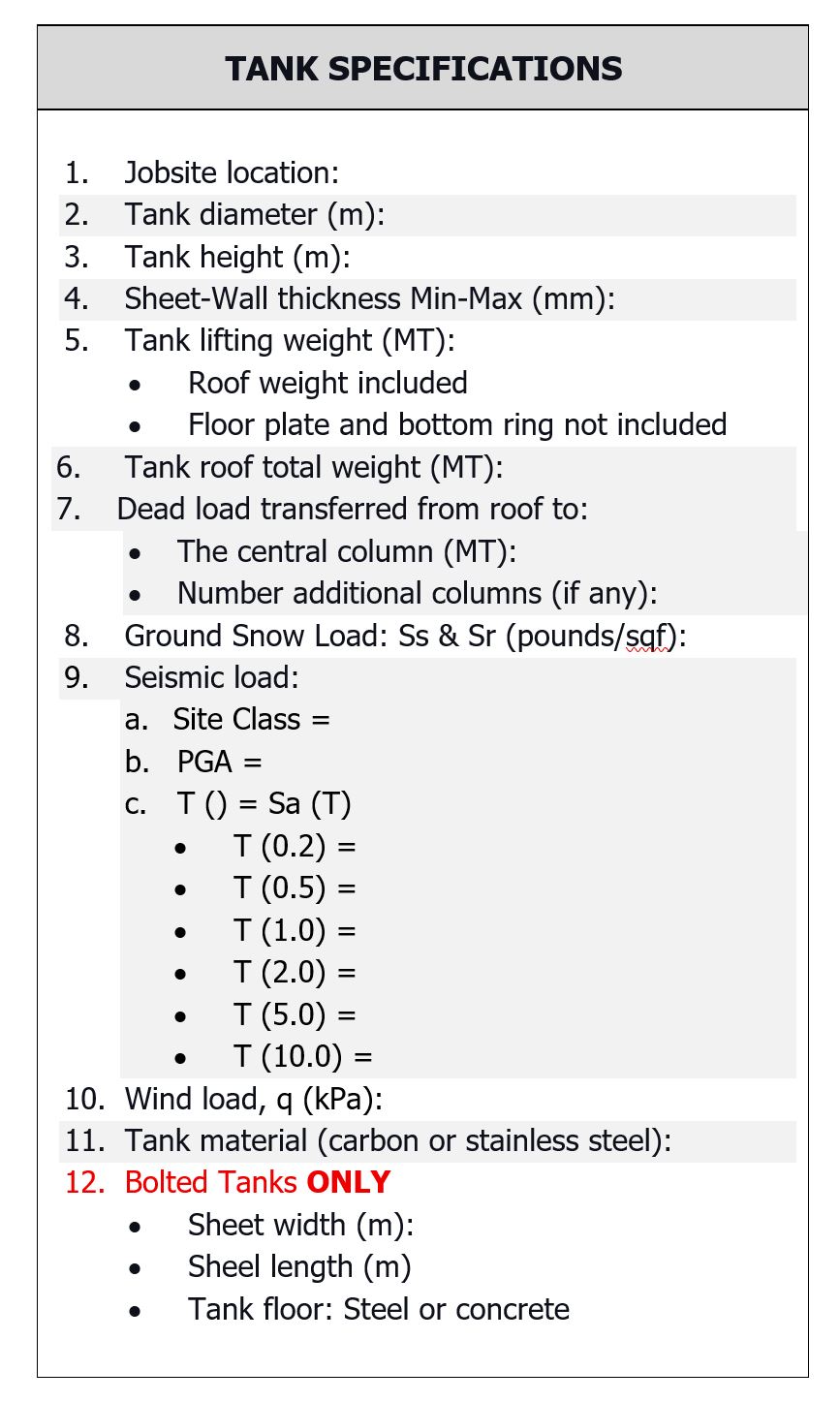

Interested parties seeking a quote should provide the accurate tank specifications listed below. This information is essential for Irizar to determine the correct number of jacks required to lift the tank safely. If any information changes, please notify us immediately.

Specifications:

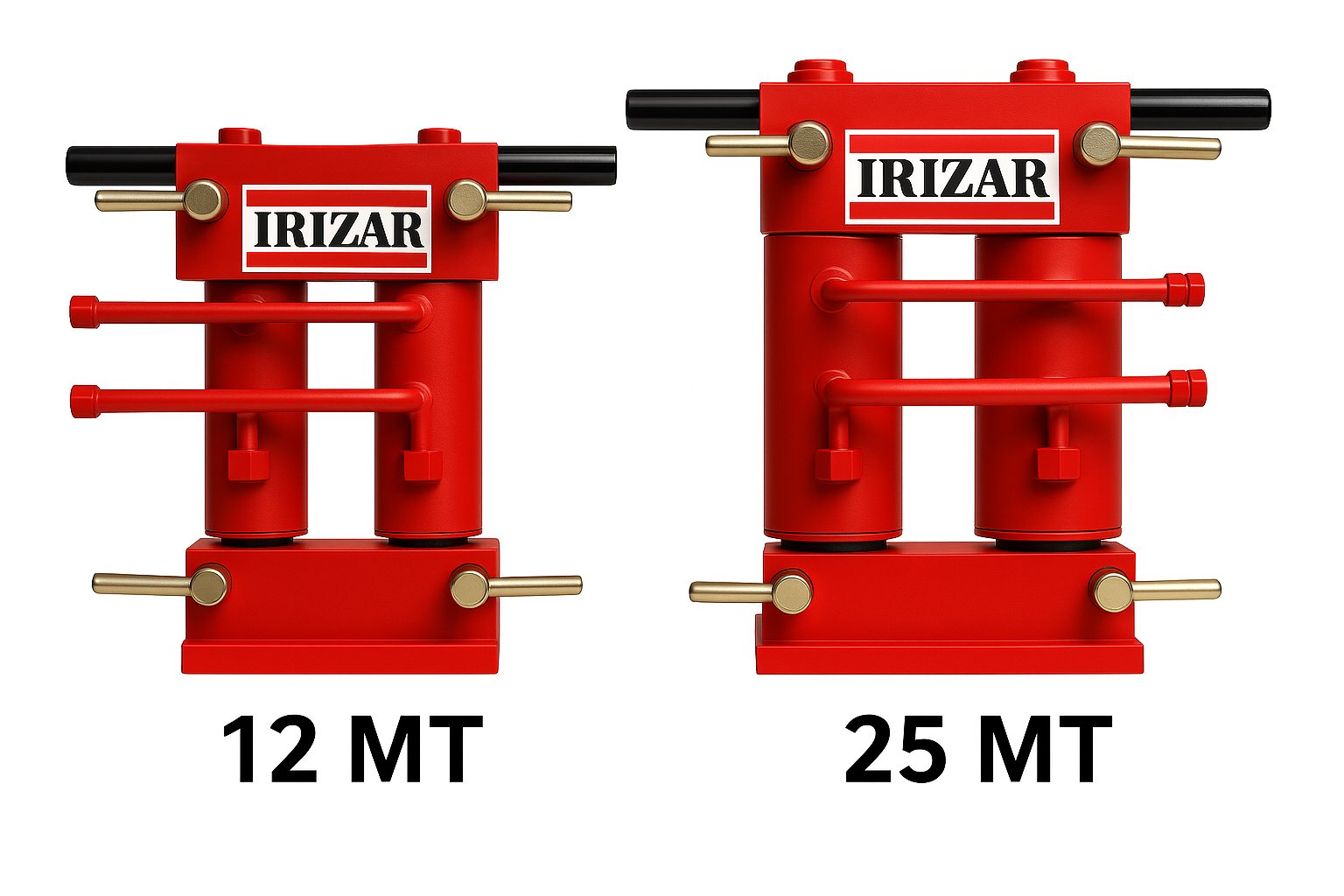

Working capacity: 12 MT

Jack type: Double action

Minimum tank diameter: 5.0 m

Minimum shell thickness: 3.175 mm (1/8”)

Minimum shell height: 1.35 m

Maximum shell height: 3.00 m

Minimum-Maximum arc distance between jacks: 1.5 to 3.0 m

Jack unitary climb: 100 mm/stroke

Lifting time/stroke: 0.45 to 1.55 minutes

Jack's weight: 60 kilos

Accessories weight: 260 kilos

Packing weight: 40 kilos

Total weight: 360 kilos/jack

-

irizar tank lifting jacks

-

irizar tank lifting jacks 11

-

irizar tank lifting jacks

-

irizar tank lifting jacks 1

-

irizar tank lifting jacks

-

irizar tank lifting jacks

-

irizar lifting jacks model 12 mt000

-

irizar lifting jacks model 12 mt 3000

-

irizar lifting jacks model2 mt 3000

-

irizar tank lifting jacks

-

irizar tank lifting jacks

-

irizar tank lifting jacks

-

irizar tank lifting jacks 2

-

irizar tank lifting jacks 12

-

irizar tank lifting jacks

-

irizar tank lifting jacks 3

-

irizar tank lifting jacks

-

irizar tank lifting jacks 4

-

irizar tank lifting jacks

-

irizar tank lifting jacks 5

-

irizar tank lifting jacks

-

irizar tank lifting jacks 6

-

irizar tank lifting jacks

-

irizar tank lifting jacks 7

-

irizar tank lifting jacks

-

irizar tank lifting jacks 8

-

irizar tank lifting jacks

-

irizar tank lifting jacks 9

-

irizar tank lifting jacks

-

irizar tank lifting jacks

-

irizar tank lifting jacks

-

irizar tank lifting jacks 13

-

irizar tank lifting jacks

-

irizar tank lifting jacks 14

-

irizar tank lifting jacks

-

irizar tank lifting jacks 15

-

irizar tank lifting jacks

-

irizar tank lifting jacks 16

-

irizar tank lifting jacks 17

-

irizar tank lifting jacks

-

irizar tank lifting jacks

-

irizar tank lifting jacks columns shipping

-

irizar tank lifting jacks columns

-

irizar tank lifting jacks shipping

-

irizar tank lifting jacks shipping

-

irizar tank lifting jakcs

-

irizar tank lifting jacks

Hydraulic Power Packs:

10 HP, Max 34 jacks

20 HP, Max 65 jacks

40 HP, Max 115 jacks

60 HP, Max 150 jacks

![]() PLC CONTROL BOX

PLC CONTROL BOX

It is recommended for lifting SLIM API/UL TANKS -welded or bolted- with a height-to-diameter ratio of 2:1 to 4:1, provided the lifting load, wind load, and seismic loads are within acceptable limits. Subcontractors must engineer internal rings, external strongbacks and finite element analysis (FEA). The PLC precisely controls the jack’s stroke, enabling the tank to be level lifted to avoid shell distortion, uneven stress, buckling, or cracking at welds. Typical lifting tolerance on small/medium tanks ≤15 mm; large tanks (>30 m diameter): ≤ 25 mm. The system features displacement sensors and a manifold block equipped with eight proportional valves. Included: 1. Touch panel. 2. DC Power supply, 110 V, 50/60 Hz, 3P. 3. Potentiometer string linear position sensors from 0 to 500 mm, and 20 m cable. 4. Enclosure hard-box. 5. Manifold Block Type BB with eight output ports & eight proportional valves. Each valve controls five lifting jacks; therefore, forty jacks are controlled by them. Application: Use the PLC Control Box to synchronize Irizar Double Action Tank Lifting Jacks, either Model 12 MT-3000 or Model 25 MT-3000.

Training: Available at our Wetaskiwin, Alberta Training Facility in a real-life environment or as an online course; both include 24/7 WhatsApp Tech Support for one year. The course is designed to be completed within one day and can accommodate up to three operators. Completion of this course is required to receive a warranty.

Delivery Time:

Within Canada: Three to five business days

USA & US-Mexican border: One week

Latino America: Four weeks

World-Wide: Five to six weeks