Description:

A Welding Gantry, also known as a Welding Automation Gantry, is a type of industrial equipment used in automated welding processes. It typically consists of a rigid structure that spans over the work area. The gantry system is often used in manufacturing environments where repetitive welding tasks need to be performed with high precision and efficiency. Welding Gantries offer several advantages in industrial manufacturing, including increased productivity, improved weld quality, and reduced labor costs. They are commonly used in automotive manufacturing, aerospace, shipbuilding, and construction industries.

Specifications:

Tank diameter: From 4.0 m to 9.50 m

Platform vertical lifting speed: 1.0 m/minute

Trolley transportation speed: 1.20 m/minute

Longitudinal effective length: 3.0 m

Welding head with 90 ͦ rotation: included

Gantry maximum load capacity: 2 MT

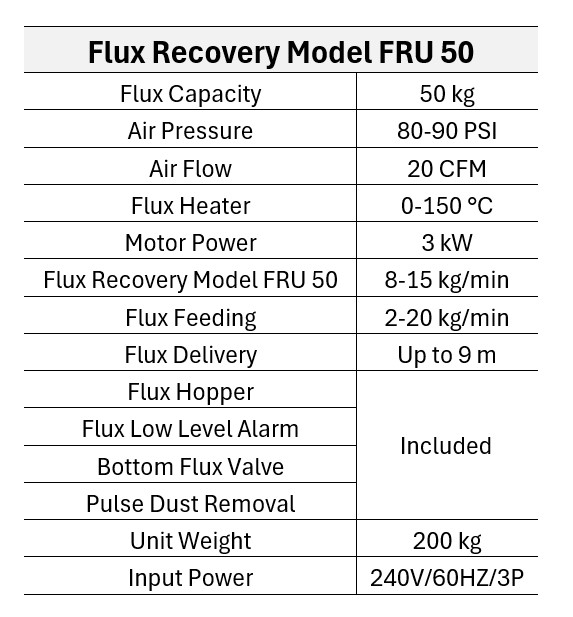

Flux recovery system Model FRU-150 with heater

Notes:

1. The Welding Procedure Specifications (WPS) and the Procedure Qualifications Records (PQR) must be qualified by the user, considering the applicable Codes and Standards. It should be designed by a welding engineer who selects the essential welding parameters such as joint design, base material, wall thickness range, filler metal, position, pre-heating temp, flux, amperes, voltage, welding speed, etc. The user is responsible for certifying WPS & PQR before deploying the equipment at the job site.

2. The Welder Qualification Test (WQT) remains the user’s responsibility. It is not Irizar's scope to train submerged arc operators; the user shall have/hire an experienced welder’s operator(s) with an updated WQT ticket(s).

Delivery Time: