AUTO TANK WELDERS

![]()

FREQUENTLY ASKED QUESTIONS [FAQ]

1. Does Irizar provide the WPS & PQR? No!. Irizar Heavy Industries recommends consulting a Certified Welding Engineer (CWEng) to design the welding procedure in accordance with the relevant national and provincial codes and standards. In Canada, CWEngs are certified by the Canadian Welding Bureau (CWB). In contrast, in the USA, they are accredited by the American Society of Mechanical Engineers (ASME), the American Welding Society (AWS), and the American Petroleum Institute (API), among other prestigious organizations worldwide. A CWEng is responsible for designing and selecting appropriate welding parameters, including plate beveling, wire and flux specifications, amperage, voltage, and welding speed, among other factors.

2. Does Irizar provide the training? No!. Irizar does not offer training, as the machine is straightforward to operate. However, it must be operated by an experienced Submerged Arc Welding (SAW) Operator. Certification is required for this trade, meaning the operator holds a journeyman certification. Irizar rental facility is available in Wetaskiwin, AB, Canada, where customer welder operators can familiarize themselves with the equipment and obtain coupons for qualifying Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), and Welder Qualification Tests (WQT). Otherwise, we recommend purchasing the machine in advance and making it work in your shop before setting it up on the jobsite.

KNOWLEDGE BASE [KB]

1. Auto Tank Welder, also known as Girth Welders, 3 O'Clock Welder, Automatic Girth Welder, AGW Welding or Automatic Tank Welder, are designed explicitly for welding Field Storage Tanks, large cylindrical vessels or ships. These systems feature automation and optimization that enhance efficiency, accuracy, and consistency in the Submerged Arc Welding Process (SAW). Here are the key features and aspects associated with Auto Tank Welders:

2. Rotation Movement: Auto Tank Welders incorporate rotational movement with motorized variable speed, which enables the turning of cylindrical tanks during the welding process. The smooth rotation ensures the welding head covers the entire perimeter of the tank, producing uniform, complete welds.

3. Welding Head: Auto Tank Welders typically feature an automated SAW welding head, ensuring consistent and repeatable welds.

4. Control Box: The Auto Tank Welder features an integrated control panel, enabling operators to set and control various welding parameters. This includes rotation speed, welding current, travel speed, and other essential settings.

5. Safety Features: Include an emergency stop button and protective measures to ensure the well-being of operators and prevent accidents.

6. Welding Processes: Welders come with a Power Source, Welding Head and Welding Controller for Submerged Arc welding (SAW).

7. Versatile: Their adjustability enables the welding of tanks with varying diameters, lengths, and wall thicknesses.

8. Applications: Auto Tank Welders are commonly used in industries such as oil and gas, petrochemical, chemical processing, water treatment, and storage tank manufacturing. They are particularly beneficial for large-scale tank fabrication projects.

9, Quality: Significantly enhance the efficiency and precision of tank welding operations, making them well-suited for industries that require the fabrication of cylindrical vessels. Their automation capabilities increase productivity and improve weld quality.

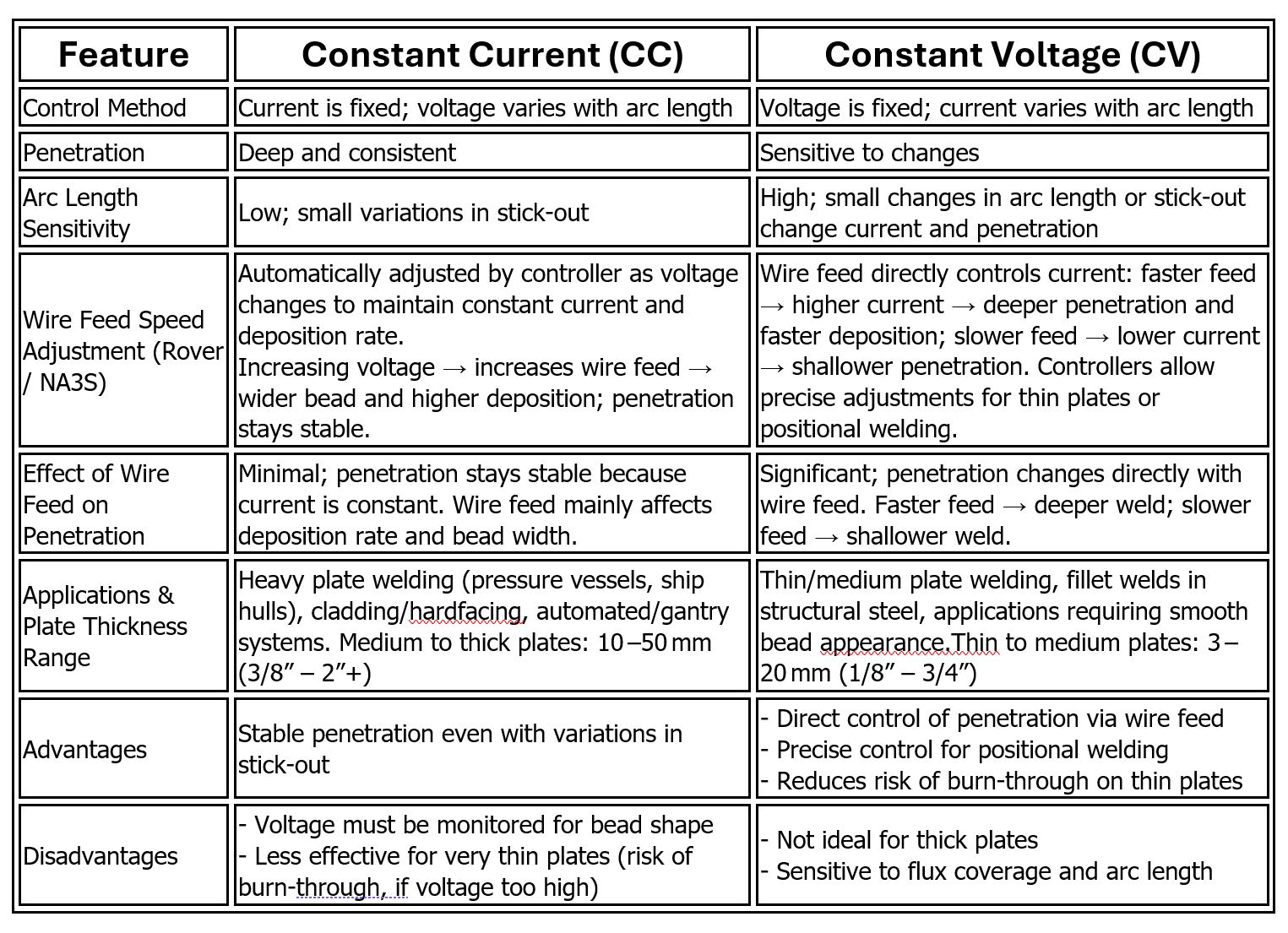

10. SAW systems operate in either Constant Current (CC) or Constant Voltage (CV) modes: Each offers different control characteristics, penetration behaviour, and suitability for various plate thicknesses. Lincoln Power Sources DC 1000, Flex Tech 650 X, or Power Plus 1000 HD, along with Lincoln Controller NA-3S (analog), NA-4 (digital), or the Lincoln Rover Controller, can operate in both CC (Constant Current) and CV (Constant Voltage) Modes. Switching from one mode to another requires changes on the Power Source front panel as well as on the Controller’s Internal Board (Toggle Switch). Lincoln Wire Feeder Head NA-3SF or Irizar Wire Feeder drive at a constant positioning speed to help position the electrode prior to welding. The actual programmed welding wire feed speed adjustment does not occur until an arc has been successfully established — this transition is triggered by sensing weld current or arc voltage, depending on whether the system is configured in [CC or CV mode]. Once the arc is detected, the controller logic switches from constant speed to the set welding wire variable feed speed.

11. Comparison Table: CC vs CV