WELDING MANIPULATORS

FREQUENTLY ASKED QUESTIONS [FAQ]

1. How to select a Welding Manipulator?

• Boom vertical expansion should be higher than the vessel diameter, which is most significant for welding.

• Maximum load at the Boom extremity will not exceed the rated range

• The shop overhead crane should be higher than the column height

2. What are the features of the Irizar Manipulator?

• Boom expansion (in-out): Motorized with variable speed from 0.12 to 1.20 m/minute

• Boom lifting (up-down): Motorized

• Column Rotation ± 180º: Motorized

• Trolley (Base): Motorized with a translation speed of 1.5 m/minute

• Boom anti-fall safety device

• Trolley anti-fall safety device

• Remote control box 12 m cable: Included

• Wireless control: Optional

• Flux Recovery System: Optional

• Manual or motorized cross slide: Optional

• Seam Tracker: Optional

3. Does Irizar provide the WPS & PQR? No!. Irizar Heavy Industries recommends consulting a Certified Welding Engineer (CWEng) to design the welding procedure following the relevant national and provincial codes and standards. In Canada, CWEngs are certified by The Canadian Welding Bureau (CWB). In contrast, in the USA, they are accredited by the American Society of Mechanical Engineers (ASME), the American Welding Society (AWS), and the American Petroleum Institute (API), among other prestigious organizations worldwide. A CWEng is responsible for designing and selecting the appropriate welding parameters, which include plate beveling, wire and flux specifications, amperage, voltage, and welding speed, among other factors.

4. Does Irizar provide the training? No!. Irizar does not offer training, as the Manipulator is straightforward to operate. However, it must be operated by an experienced Submerged Arc Welding (SAW) Operator. Certification is required for this trade, meaning the operator holds a certification as a journeyman. Irizar rental facility is available in Wetaskiwin, AB, Canada, where customer welder operators can familiarize themselves with the equipment and obtain coupons for qualifying Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), and Welder Qualification Tests (WQT). Otherwise, we recommend purchasing the machine in advance and making it work in your shop before setting it up on the jobsite.

KNOWLEDGE BASE [KB]

A welding manipulator is used for automated SAW / MIG / FCAW / TIG welding on pipe, tank, and pressure vessels, combined with Tank Turning Rolls, Welding Positioners, or Head & Tailstock Positioners. It helps automate and improve the quality of the welding process, especially for large or complex parts. Irizar manipulators mainly comprise a column, boom and motorized trolley (travelling car). We supply the manipulator itself loaded with power source, welding head, welding controller, flux recovery system, motorized cross slide & seam tracker. Welding Manipulators are also known as Welding Booms, Welding Columns or Welding Column and Booms (C&B)

1. Axes of Movement: Welding manipulators feature multiple axes of movement, such as: Vertical (up and down): Allows for height adjustments. Horizontal (side-to-side): Allows for lateral movement.

2. Automation: Some manipulators are part of a fully automated system that adjusts positioning, speeds, and even the welding parameters, based on the specific requirements of the welding task. In this case, the manipulator may be controlled by a computer or programmable logic controller (PLC).

3. Applications: Used in shipbuilding, aerospace, gas and oil pressure vessels, pipe welding, and large-scale manufacturing, where precision and efficiency are crucial. In essence, a welding manipulator improves efficiency, precision, and safety during welding operations by minimizing manual intervention and allowing for consistent, high-quality welds.

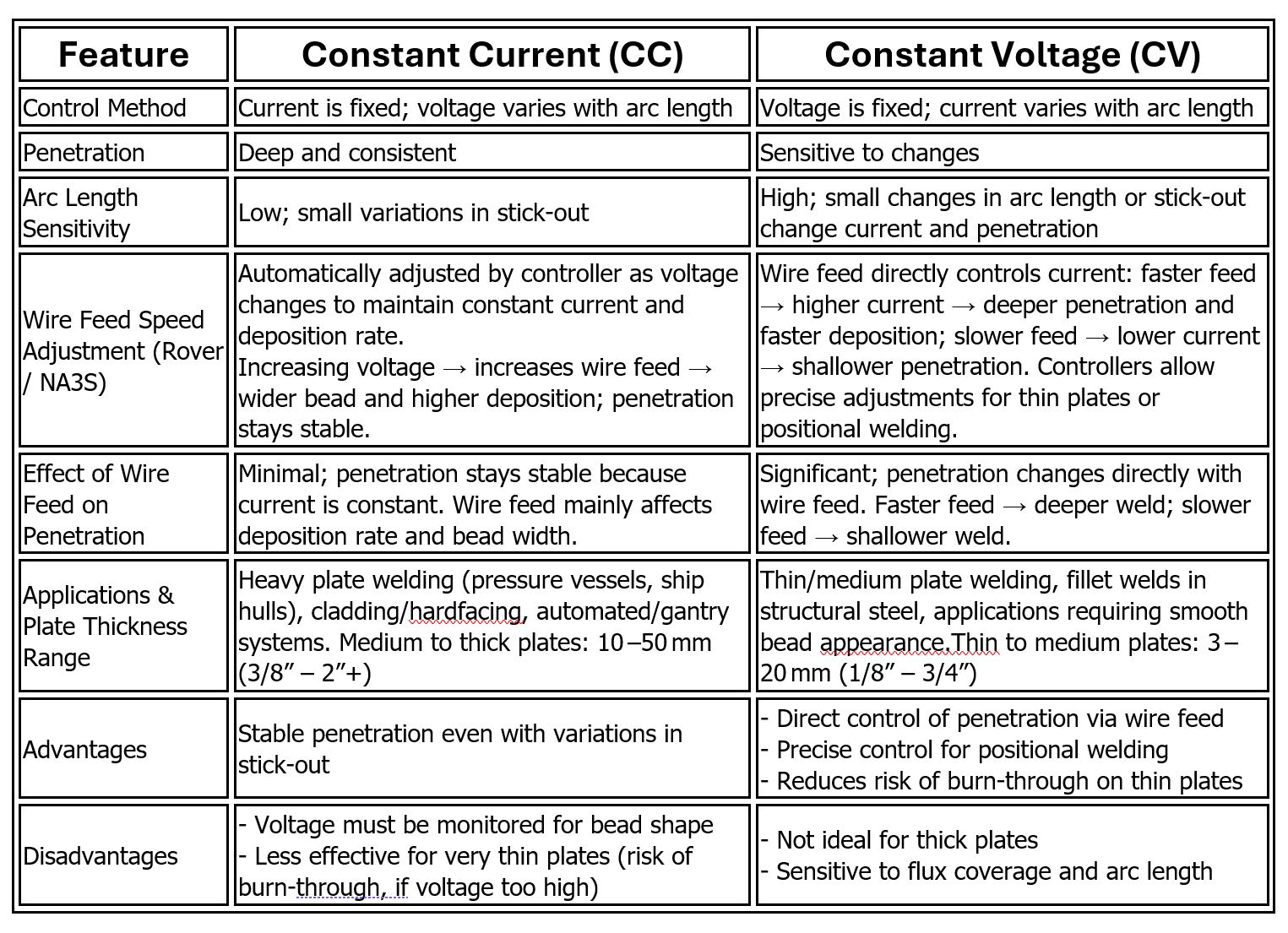

4. SAW systems operate in either Constant Current (CC) or Constant Voltage (CV) modes: Each offers different control characteristics, penetration behaviour, and suitability for various plate thicknesses. Lincoln Power Sources DC 1000, Flex Tech 650 X, or Power Plus 1000 HD, along with Lincoln Controller NA-3S (analog), NA-4 (digital), or the Lincoln Rover Controller, can operate in both CC (Constant Current) and CV (Constant Voltage) Modes. Switching from one mode to another requires changes on the Power Source front panel as well as on the Controller’s Internal Board (Toggle Switch). Lincoln Wire Feeder Head NA-3SF or Irizar Wire Feeder drive at a constant positioning speed to help position the electrode prior to welding. The actual programmed welding wire feed speed adjustment does not occur until an arc has been successfully established — this transition is triggered by sensing weld current or arc voltage, depending on whether the system is configured in [CC or CV mode]. Once the arc is detected, the controller logic switches from constant speed to the set welding wire variable feed speed.

5. Comparison Table: CC vs CV